One pizza company used the effective branding statement, “Better Ingredients Makes Better Pizza”. This statement holds true to making better cleaning solutions. Just like there are grades of cheese, pepperoni, sauce, etc., there are grades of raw materials used in making cleaning solutions.

The different grades of d’limonene are among the more obvious to the cleaner. Distillates, technical grade, and food grade are distinguished by the consistency of the fragrance. The odor of a poor distillate will not easily be forgotten.

The amount of the ingredient used in any formula matters. However, we need to go beyond the quality and amount of the ingredient and also find special ingredients with core performance features that improve cleaning results. It is important to properly select ingredients that highlight a core feature that creates unique cleaning solutions and provides consistent results.

Each blog in this series will focus on a different feature brought about by a distinctive raw material based on performance and not cost. We will show pictures and/or short videos that visually illustrate performance from adding this raw material that by itself is uniquely responsible for that aspect of the result. The art of the formulator is in the selection of these quality, innovative raws with features that produce reliable results for each application.

It starts and ends with the science of cleaning.

Soil Resistance

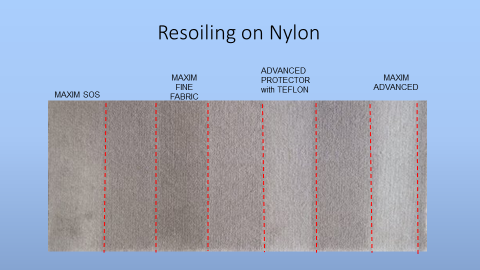

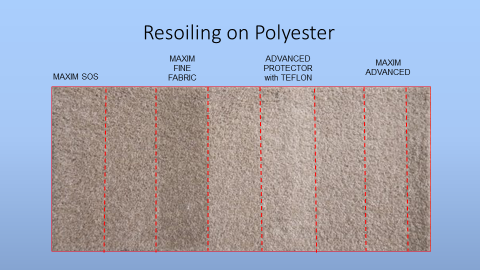

Soil resistance is a common trait of water-based fluorochemical carpet treatments; all treatments that we have tested keep both nylon and polyester carpets cleaner longer. In most cases, they work better on nylon than on polyester. In contrast, solvent-based fluorochemical treatments fail, in most cases, at keeping nylon and polyester cleaner longer. In this century, polymers have been used in “green” protector formulas to provide soil and stain resistance.

These polymers have also been used in cleaning formulas to provide soil resistance or to at least not cause re-soiling.

Encapsulation formulas have been developed whose performance is carefully balanced between cleaning performance and soil resistance. The concept of this low moisture cleaning is to get the carpet clean and keep it clean until the next maintenance cleaning is performed. It became a necessity to add these polymers to spotters and pre-sprays in order to pass the Carpet Rug Institute test on soil resistance.

Ask me how I know?

The following video shows how nylon carpets treated with soil-resistant polymers and one untreated respond to synthetic soils. You can see how quickly the soil bonds to the untreated fiber and is repelled by the treated fiber.

There are several polymers in our arsenal that we put into cleaning solutions. We use one primarily for our two polymer protector formulas, but it is also used in 39 other formulas. This polymer has some stain-resistant characteristics but is more useful when we want to add more soil resistance and anti-wicking properties.

Education beyond blogs

Hands-on Rug Cleaning Aramsco/ Interlink Supply Training Schedule (cvent.com)

Carpet Cleaning Technician

Featured Products

Hydro-Force, Carpet Protector, Advanced Protector, 1 Gallon

Bridgepoint Systems, Carpet Protector, Encapuguard Green, 1 Gallon

Bridgepoint Systems, Carpet Protector, Maxim S.O.S. Stain, Odor, & Soil, 1 Gallon