A fundamental change in carpet fibers this century has put polyester and nylon spotting instructions on somewhat different tracks.

For more than 40 years, nylon fibers dominated broadloom carpet sales while less expensive fibers such as polyester (in various proprietary forms) or olefin fibers were in the minority.

Clear separation in terms of pricing between the two fibers existed. This often resulted in better maintenance for nylon than polyester, based on both the perceived and real differences in quality. Nylon carpet was worth the cost of maintenance, due to its quality as well as its price, whereas Polyester carpet was often considered to be more disposable and expected to be replaced in a much shorter time frame.

Changing Times in Treating Spots and Stains

We are currently in a much different place with carpet fibers.

There is no longer a clear separation between nylon and polyester due to manufacturing improvements with polyester and the way that it is marketed. Polyester is still not the quality of nylon, but it is a better product than in years past (names you might recognize are SmartStrand (Triexta) etc).

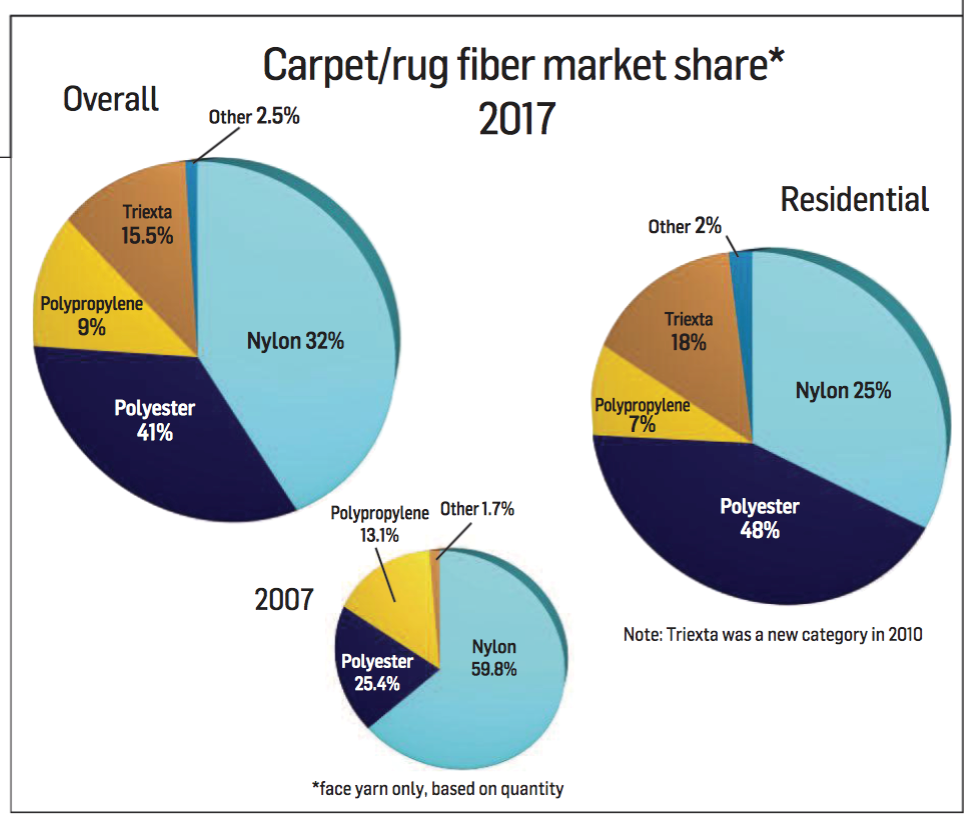

These improvements, combined with the lower cost of manufacturing, have greatly changed the landscape in terms of polyester sales (now over 70% of new carpet sales), and what contractors come across on a daily basis.

(Photo courtesy of Floor Covering News. Used with their permission)

Most spotting chemistry was designed for nylon due to the demand that was driven by high sales as well as the fiber’s characteristics.

Nylon can absorb moisture and has open dye sites that can be filled with staining material.

Polyester does not absorb moisture and will not stain from typical foods and fluids, but it does have a tendency to bond with oils which can create its own set of challenges.

Spotting chemicals are divided into two categories: targeting spots and stains. Spots are typically substance spills and are more easily removed. Stains are traditionally considered to be an alteration to the color of the fiber and may be difficult to remove or require more advanced chemistry or procedures.

One group works to make stains invisible through different chemical mechanisms, usually with reducers or oxidizers. The other group works to release spots (foreign materials) from the surface of fibers. Another group of issues might need both for complete success.

Putting the Chemistry to a Test

I recently taught a spotting class where I used both nylon and polyester carpet. For a demonstration, Kool-Aid and wine were spilled on both samples.

For the nylon carpet, the Kool-Aid, (a synthetic dye), we applied a reducing agent to make the Kool-Aid (a synthetic dye) invisible. We made the wine (an organic dye), invisible by using an oxidizing agent.

It was unnecessary to use advanced chemistry on the polyester sample because, as stated earlier, polyester is non-absorbent, and the Kool-Aid and wine were easily rinsed away (This isn’t to say one fiber is better than another. It’s simply to say different fibers have different characteristics and professionals should be sure they are using the appropriate chemistry and procedure to improve their success rate.)

Students also realized that products designed to release sticky substances such as gum, adhesives, inks, paints, globs of soils and oils, etc. were needed for both the nylon and polyester carpets. In these cases, the spills dictated the need rather than the fiber.

Main Takeaway and Conclusion

The category of spotters used to release bonded substances will likely be more in demand for the immediate future since polyester carpet is the highest percentage of carpet sold. Oxidizers and reducers will likely be used less often where nylon is no longer dominant.

A contractor should be well educated on how to identify fibers as well as what spotter is best suited for maintaining them.

Welcome to the new world of spotting!

Take your education beyond our blogs:

Profit Builder Series Advanced Hands-On Spotting

Aramsco/ Interlink Supply Training Schedule (cvent.com)

Featured Products

Bridgepoint Systems, Stain Remover, Red Zone Ready One-Part Red Stain Remover, 1 Quart

Bridgepoint Systems, Stain Remover, Stain Zone, Oxidizer, 1 Quart

Bridgepoint Systems, Stain Remover, Gel Break Adhesive Remover, 1 Pint