As consumers’ demand for environmentally-friendly cleaning grows, chemical manufacturers strive to formulate greener, safer products. They increasingly use enzymes or enzyme-producing bacteria in their formulations, which will lead to effective cleaning even with a reduced amount of surfactant and without strong additives. This is good for the environment, but is it safe for wool? Will the enzymes damage the wool in the carpet once they finished breaking down the protein in the staining?

WoolSafe had to investigate this.

In the initial experiments, we used one product, a deodorizer, in different concentrations on a multi-colored 80% wool/20% nylon carpet. New and pre-worn carpet pieces were treated to see whether the damage was more likely on fibres already weakened by traffic. The deodorizer was sprayed on as recommended, making the carpet slightly damp. After thorough drying, the treatment was repeated three times to simulate multiple applications. We did not observe any change in the carpet’s appearance or handle even by the highest product application rate. None of the colours were affected either.

The change of the pile height of all the differently treated samples was monitored whilst worn in the Hexapod machine, and we found no difference. Similarly, there was no difference between the amount of fibre shed by the differently treated samples during the test.

Encouraged by these results, we widened the range of products and included a urine treatment, a pre-spray in the new experiments, and a spotter with the deodorizer, all from different manufacturers. This time we used the standard test carpet: 100% undyed, double-scoured wool.

First, we made sure all the products that we used satisfied the standard WoolSafe criteria. Next, we treated the carpet samples with the maximum recommended dose six times, over a two-week period. After thorough drying and vacuuming, they were subjected to accelerated wear in the Hexapod machine, all together for 8000 revolutions, which represents 5 years of wear. After every 1000 revolutions the samples were vacuumed, the shed fibres collected, and the pile height measured.

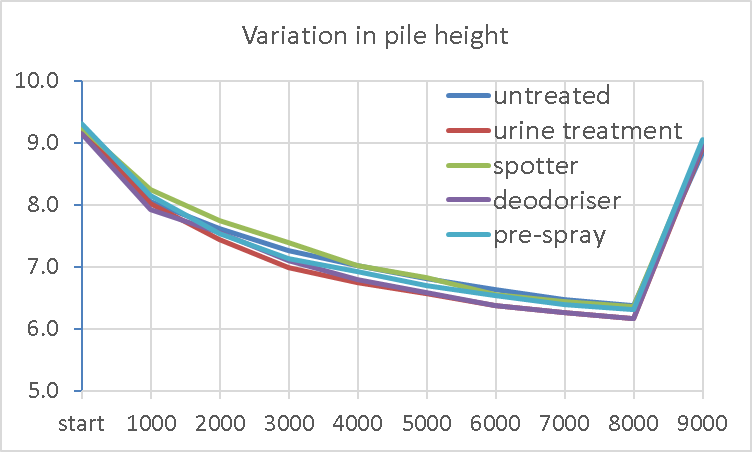

Picture 1. Change of pile height during wear and after extraction with water.*

*Picture 1. shows that there is no significant difference between the decrease in pile height of the differently treated and the untreated sample. Moreover, when the samples later were extracted with warm water (in preparation for the alkaline solubility tests), all samples regained the lost height, confirming the lack of damage.

Shedding during the experiment was minimal and similar for all treatments; if one of the enzyme-containing products had caused damage to the fibre, there would have been increased shedding.

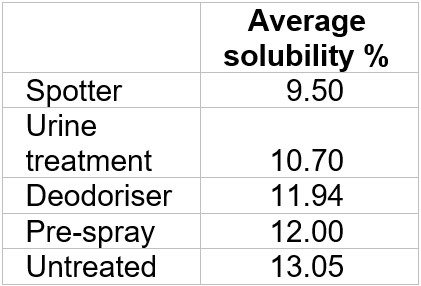

Another experiment often used to detect damage caused to wool fibres is the alkaline solubility test (ASTM D1283-05). The experiment involves dissolving a known amount of wool fibre in sodium hydroxide. Undamaged scoured wool has a typical alkali-solubility of 9 – 15%. Any deviation from that can indicate damage. First, we established the alkaline solubility of the wool from the untreated test carpet. The four samples gave an average solubility of 13.05% ±2.7%. The alkaline solubility of all samples is shown in Table 1.

Table 1. Alkaline solubility test results

Table 1. Alkaline solubility test results

The last three figures are within tolerances, but the decreased solubility of the wool treated with the spotter and the urine treatment was slightly concerning. It could indicate that the treatment itself had already dissolved some of the fibre, decreasing the amount available to dissolve in the experiment. On the other hand, a high degree of damage would have opened more of the fibre, so solubility would have increased.

To get a better picture of what was happening to the fibres, we sent multiple samples of each treated and not treated carpets so that they could be investigated with scanning electron microscopy. Only one of the samples treated with the spotter had some observable damage to the cortical cells; all other samples were the same as the untreated one and had no visible damage that could be attributed to the enzyme.

If the enzyme had attacked the fibre, we would have observed increased shedding, poor wear characteristics, and damage to the fibres when investigated by scanning electron microscopy, but none of these occurred at a significant level. In these experiments, we used extreme circumstances, much higher than the recommended dosage over a long period of time without rinsing. We can reasonably assume that under normal usage none of these products would cause damage to wool carpets. As mentioned before, all of these products have satisfied the standard WoolSafe requirements.

Conclusion

We cannot see any reason for excluding products from WoolSafe testing simply because they contain enzymes. However, we still recommend thorough rinsing once finished.

This article was originally written by Dr. Ágnes Zsednai and is published with their permission.