On the surface, masks and respirators might not seem like a particularly exciting topic. I wouldn't blame you if you viewed personal protective equipment (PPE) as a necessary evil that stands in the way of your real work.

In reality, though, masks are foundational to your professional success.

Wearing a proper respirator will set you up as a professional, is legally required by OSHA, and will help you accomplish work that would otherwise be impossible (or deadly) when working with chemicals, vapors, gases, and other harmful materials.

I'm going to show you the steps involved in choosing the right mask and the options that are available so that you can make the right choice.

Protecting Yourself With the Right Mask or Respirator on the Job

The Occupational Safety and Health Administration (OSHA) requires by law that a written Respiratory Protection Program is posted at your job site whenever a potential hazard is present. U.S. Occupational Safety and Health Administration (OSHA) regulation 29 CFR 191.134 is the section of the OSHA code that covers the technical requirements for what must be included in this plan and the standards that you must follow.

I'm not going to cover every aspect of what a respirator plan should include in this post, but for our purposes here you should know that:

- As an employer, you MUST provide the proper mask or respirator to each employee that will be present at a job site.

- You must have a written Respiratory Protection Program implemented by a program administrator. This requires:

- A medical evaluation completed for each employee

- A fit test of the mask for each employee to make sure that the mask fits properly and doesn't let in any chemicals (a fit test remains valid as long as you stick to the same mask supplier)

- Training and guidance provided to each employee about the hazards that they will be exposed to and how to properly wear their mask

By following these guidelines for implementing a written respiratory program, you will avoid sickness, injuries, fines, or death when working in hazardous conditions.

Identifying Workplace Hazards and Conducting a Fit Test

"What contents are in the room? You have to determine what filter you need for a specification. It's not a one-size-fits-all. It really depends on what you're working with," Jennifer Miller, Aramsco's product manager of PPE elaborates.

Before you start a job, you have to know what contaminants your employees will be exposed to. Each contaminant that you face poses a different health risk that varies depending on the level of concentration of the contaminant that is present. Every contaminant requires a different level of protection and the proper mask filter.

Remember this:

- Every contaminant has a set Permissible Level of Exposure (PLE) for the eight-hour workday that is determined by OSHA. This is the acceptable amount of the contaminant that can be present before a suitable mask is required by law.

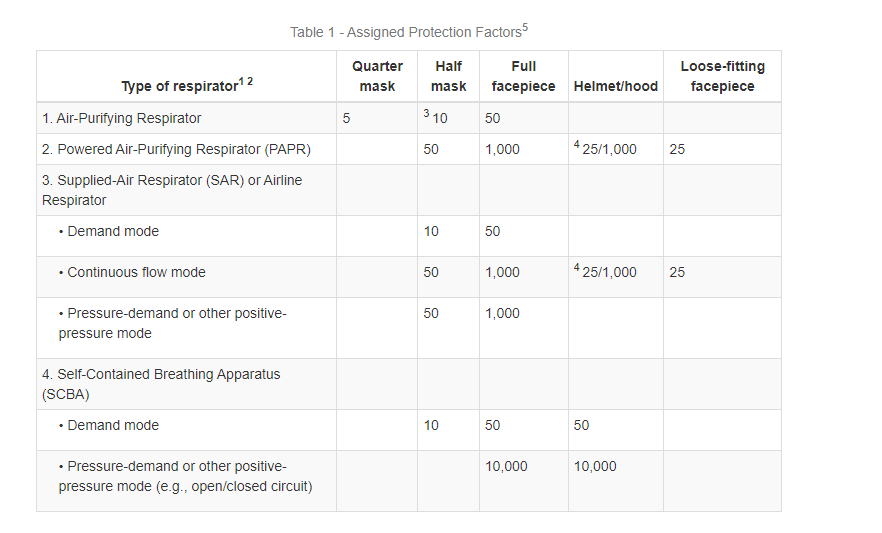

- A suitable mask is one that has an Assigned Protection Factor (APF) suitable for the level of exposure.

- There is a maximum use concentration (MUC) that the mask is viable for that is determined by multiplying the PLE and the APF. In other words (PEL) X (APF) = (MUC). This is the highest level of concentration that the mask is able to protect against.

- Which filter do you need? You need the proper filter. "A filter is required to be changed at the end of each job," Miller says. Many contractors forget to change the filter or become lax about doing this, but this is essential

The above chart is taken from the OSHA handbook and contains the assigned protection factors for each type of mask.

Before moving on, let's take a moment to review:

- The right mask/respirator is required by law to keep your employees safe

- You can't pick the right mask or respirator without a knowledge of the concentration of the hazards you will be facing and picking a mask that has an APF above the level of exposure you will be facing.

We will consider the different types of masks below.

The Types of Masks/Respirators and the Protection that they Offer

There are four types of masks that each provide varying levels of protection. Once you have determined the environmental contaminants and the APF needed using the information above, you can select a mask that has the correct APF.

These are the four types of masks available:

Basic Dust Mask

A disposable basic dust mask is a mask that provides simple protection from non-toxic dust particles, non-toxic mold, and dander. These masks are used to protect against nuisances like dust and are NOT NIOSH approved. Contractors essentially wear them for convenience and comfort on the job.

N95

An N95 mask received its name because of its ability to remove 95 percent of .3+ micron particles. The "N" in the name stands for non-oil and represents the classification of the mask. You can only use this type of mask in an environment where non-oil-based contaminants are present. This respirator is NIOSH-approved and requires a medical test and fit test prior to wearing it on the job. An N95 provides an APF of 10.

To put it simply, an N95 is typically the bare minimum standard of protection required when working in a hazardous environment. An N95 is disposed of after use.

Non-Powered Air Purifying Respirator (APR)

An APR is a respirator without a motor that relies on the wearer's breathing to pull air from the surrounding environment. This type of respirator has an APF of up to 50 and provides a higher level of protection than a traditional N95.

Similar to an N95, an APR respirator relies on the user to draw air through the mask's filtration device.

APRs must be fit-tested, and you cannot have more than one day of facial hair growth when wearing one to ensure that it fits properly. An APR is a respirator that is reusable and must be cleaned properly.

Powered Air Purifying Respirator (PAPR)

A PAPR is a powered air-purifying respirator. The greatest difference between an N95 and a PAPR is that a PAPR is battery-powered. A PAPR respirator is designed to automatically filter the air in the environment. The air is filtered to the mouth or face of the wearer through a breathing tube.

PAPRs provide a much greater APF than a standard N95 mask by creating an air pressure differential. When wearing an N95 mask you have to use your lungs to draw air through the respirator. In contrast, the PAPR can draw through the air on its own and have a higher APF because they are capable of drawing more air through the mask than when relying on your lungs.

The mechanical nature of the mask also makes breathing easier, saving you energy, "Contractors can work longer and harder because they don't get as fatigued because the mask regulates your breathing," Miller notes.

The APF of a PAPR respirator ranges from 25 to as high as 1,000. The high protection of a PAPR is particularly effective when combined with other safety features such as a hood, visor, or other job-specific features.

A PAPR is powered by a blower that forces ambient air through a filter cartridge. This will need to be replaced per OSHA specifications to make sure that the air is properly filtered. The batteries that power the unit usually clip onto a battery pack and will also need to be replaced or charged periodically. A high-efficiency (HE) filter is capable of filtering 99.7 percent of particulate matter at .3 microns.

If you wear a PAPR with a hood or helmet a fit test might not be required which may eliminate the need to shave. Like an APR, a PAPR respirator is reusable, so it must be cleaned properly.

Pictured above: The Honeywell PR500 Series Face-Mounted Powered Air-Purifying Respirator (PAPR) uses a blower unit to force ambient air through a single High-Efficiency Particulate Air-Purifying (HEPA) filter to remove contaminants and provide clean air to the user. This respirator is ideally suited for applications where nonpowered air-purifying respirators are not practical or a higher protection factor is required, yet where the atmospheres are not immediately dangerous to life or health (IDLH).

OSHA Required Respirators for Particular Chemicals and Substances

OSHA requires that certain types of masks or respirators must be worn when dealing with specific types of chemicals or substances. You can read the guidance provided for dealing with these hazards by clicking on the following link. Please note that the list is not comprehensive.

Conclusion

Choosing the right mask or respirator isn't just something that you decided on in the moment; It involves careful consideration of the contaminants you will be exposed to, the amount of the contaminants, and OSHA law. After you pick the right mask you must undergo a medical evaluation and a fit test by somebody that is certified to ensure that the mask provides adequate protection.

Filters for each mask are only designed to remove the chemicals specified, so the operating instructions/manufacturing instructions should always be read in detail by your program administrator prior to application.

For further reading, view the following sources below:

Enjoyed reading this post? Read the following articles:

References

1910.134 - Respiratory Protection. | Occupational Safety and Health Administration. (2011). Osha.gov. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.134

Air-Purifying Respirator - an overview | ScienceDirect Topics. (n.d.). Www.sciencedirect.com. https://www.sciencedirect.com/topics/nursing-and-health-professions/air-purifying-respirator

Dust Mask vs. Respirator | Environmental Health & Safety | Michigan State University. (n.d.). Msu.edu; Michigan State University. https://ehs.msu.edu/occ/respirator/dustmask-vs-resp.html

N95 Masks Explained. (n.d.). Www.honeywell.com. https://www.honeywell.com/us/en/news/2020/03/n95-masks-explained

OSHA Respirator Requirements for Selected Chemicals | NIOSH | CDC. (2020, February 20). Www.cdc.gov. https://www.cdc.gov/niosh/npg/nengapdxe.html

PAPR protection and when to use air purifiers. (n.d.). Honeywell; Honeywell. Retrieved May 6, 2022, from https://ppe.sps.honeywell.com/respiratory-nur2022/papr-whitepaper?utm_source=google_search&utm_medium=cpc&utm_campaign=22-q1-sps-hppe-usc-respiratory_papr_nurture&s_kwcid=AL

Regan, R. (2020, February 26). The ABCs of a Written Respiratory Program. Honeywell.com; Honeywell. https://sps.honeywell.com/us/en/support/blog/safety/the-abcs-of-a-written-respiratory-program