Are you looking for a way to prepare a concrete surface for a coating, remove stains, or remove rough spots?

There are three common methods that help prepare concrete surfaces, chemicals/acid etching, shot-blasting, or grinding. Each has its strengths and weaknesses. Keep reading to learn which method is best for different circumstances.

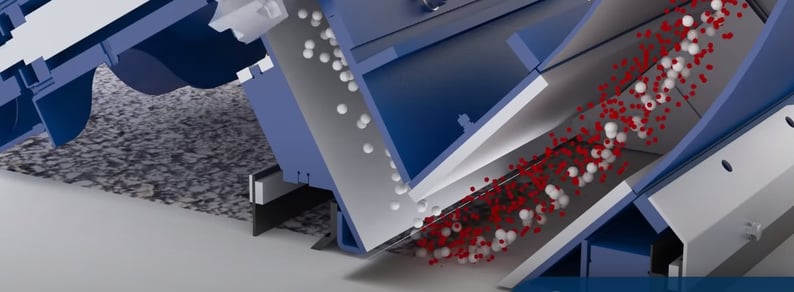

What is Concrete Shot Blasting?

Shot blasting machines for concrete are called enclosed shot blasters. These machines use centrifugal force to blast a metal media call “shot” at the floor. They are enclosed, meaning the shot is controlled in the machine.

With traditional shot blasters/sandblasters, the media is not enclosed. After impact, the media is essentially spent, as it is thrown in various directions (with an enclosed system, the shot impacts the concrete and the machine will recycle the shot back into the machine. All while cleaning up after itself). The broken shot and concrete dust is pulled into a dust collector to keep it out of the air and off of the floor.

Shot Blasting is ideal for creating a surface that is perfect for bonding coatings, overlays, toppings, etc., due to due to the way the shot removes the surface. It creates a profile that optimizes the likelihood of coatings getting good adhesion to the concrete. In some cases, manufacturers will not warranty their product unless the surface is prepared with a shot blaster.

What is Concrete Grinding?

Concrete Grinders remove layers of concrete by using diamond pads. A concrete grinder uses rotation and pressure to slowly remove one layer of concrete at a time. A diamond pad has a resin or metal that holds tiny diamond grits together. Diamond Pads come in different grits to accommodate the needs of the concrete. A dust collector is used to help remove the concrete dust. Due to the nature of grinding, this system will create more dust and more clean-up compared to a shot blaster.

Grinders have many purposes. They are good at removing layers of concrete and making a unified flat floor, but most importantly, they are good at polishing; when it comes to polishing this is the only available method. Because of the different grits and the nature of grinding, a contractor can get the concrete as smooth as they want with multiple passes and a variety of different grit diamond pads.

What is Chemical Etching?

Chemical etching is typically done with acid. Acid etching describes the process of applying hydrochloric/muriatic or buffered phosphoric acid to a concrete slab, Once the acid has an adequate dwell time, water is then used to rinse off the slab. The acid removes contaminates, reduces the surface alkalinity, and roughens the surface. When applying paint to a concrete surface these are all important aspects to get good adhesion.

*Note that this method is often discouraged in today's society due to its use of acid when there are other methods such as sandblasting and grinding available.

Which is the best method?

Shot Blasting Advantages

- Shot blasting is effective and quick to get results

- Shot blasting creates a texture on the surface for extra traction

- Shot blasters can be lighter and easier to maneuver than small walk-behind grinders

- Due to their design, shot blasters are effective at their purpose all while keeping you safe from contaminants

Grinding Advantages

- Able to fix damage and irregularities in concrete

- Work in wet or dry conditions

- Removal of rubber coatings

- The best option for polished concrete

Acid Etching Advantages

- Effective in reducing color variations, creating a more uniform colored concrete

- Opens the pores of the concrete, which enhances adhesion

- Less labor-intensive than either grinding or shot blasting

Conclusion

Which method is best for your job?

It all depends on the type of work you plan on doing. In a perfect world, you will want each machine/chemical available for the type of job you will be doing. All three of these methods are great for surface preparation. You will want to take into consideration how much of the concrete needs to be removed, what the end result needs to look like, and ultimately what the customer is looking for. In some cases and jobs, using a combination of these will get the best results.

Enjoyed reading this post? Read the following articles:

Featured Products

Blastrac, Walk Behind Shot Blaster, 1-8DM

Stonecrete Floor Grinder, Rotative, 23", Two Heads, 7.5HP, 220V, Single Phase