If you have researched the surface prep and concrete polish market, you will know that concrete grinder machines do not come cheap. As is the case with many things in life it's important to make sure we are getting exactly what we need, getting the right amount of value, and buying the best product available. The purpose of this article is to help you confidently buy a concrete floor grinder.

First, we will discuss the two head configurations of grinders, planetary and rotative. Next, we discuss the power options (This might sound unnecessary, but when it comes to voltage, phases, and propane there are lots to discuss). Finally, we will break down what to look for in the size and weight of these powerful machines.

Planetary vs. Rotative

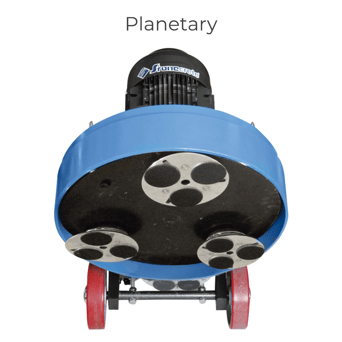

One of the first things you need to consider is choosing between a planetary or rotative machine. The terms Planetary and Rotative refer to how the discs move to get the job done. Each configuration is capable of a complete floor polish or grinding with its own specifications.

A planetary grinder has one large disc with three smaller discs mounted on it. A good way to visualize a planetary grinder is the large disc is similar to the sun, with smaller planets/discs rotating on their own axis around the sun (larger plate). The larger disc will never come into contact with the ground because its purpose is to rotate the smaller discs.

A planetary grinder is typically a lighter weight machine compared to rotative machines, which in some cases can make them more maneuverable and easier to work with. Concrete Grinders are either belt-driven or gear-driven. Planetary machine configurations are often made to be belt-driven.

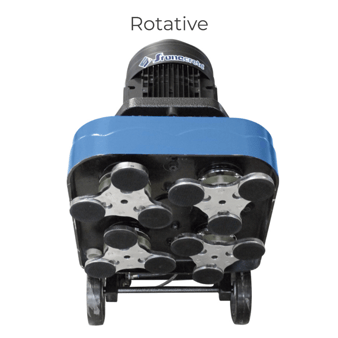

A rotary or rotative grinder turns on a fixed axis, allowing it to have multiple heads. The main limitation of this type of grinder is the width of the machine. Some rotative grinders have as many as 8-10 heads, although the most common arrangement is the 2 and 4 head configuration.

When you have multiple heads on a rotative grinder, you will most likely have a counter-rotating machine. This means the different heads rotate in opposite directions, making them easier to use for the operator and allowing the machine to go in a straight line.

Rotative Grinders are always gear-driven and heavier than planetary machines. This can make them a better choice for removing thick glues or paint.

Power Options for Concrete Floor Grinders

A concrete grinder can come in a variety of power options including electric or propane. Each of these options has factors that make them ideal for the type of work you are doing.

Electric machines typically come in 110, 220-240, or 380-480 volt machines. They also come in single-phase and three-phase configurations. 110 volt machines come in only a single phase. 220-240 volt are often offered in single-phase and three-phase. 380-480 volt are typically always a three-phase machine.

What you Need to know about Single-Phase vs Three-Phase:

Single-phase: is a two-wire alternating current (AC) power circuit, common in most residential homes. If you plan on doing only residential jobs a single phase is the way to go. The main advantage of a single-phase machine is that the equipment is typically smaller, costs less, and power is more available to use.

Three-phase: is a three-wire of alternating current power circuit. Each leg of alternating current reaches a maximum voltage. This can get complicated, but to simplify, you have more consistent power that never drops to zero. These machines are large and powerful machines that require more power consumption. Three-phase motors will cost more, but they will also generate more power, making them worth the investment.

What do I do if I don’t have three-phase on a job site, and want to use this type of machine?

What do I do if I don’t have three-phase on a job site, and want to use this type of machine?

It is a simple fix for contractors looking to take advantage of this option. You can use a phase converter to convert single-phase power to three-phase power. A phase converter creates the third line of voltage-enabling three-phase power when you are in a single phase area.

Propane machines: These machines are powerful and come with the added convenience of not having to worry about finding a power source. They have the added benefit of being often more powerful than their electric counterparts. Running on propane provides great benefits to not worrying about power, additional power cables, etc.

There are some drawbacks and challenges of propane, though. Propane grinders are loud machines. They can only be used in areas where loud noises are permitted. Therefore, if your plan is mostly commercial this will be a great option but if you plan on doing more residential a quieter electric machine might be best. Propane is also more damaging to the environment.

Size and Weight of Concrete

Is size an important factor when choosing a grinder? The answer is a bit complicated. A larger machine will get the job done faster than a smaller machine if they have a larger grinding head to complete concrete passes. A smaller machine will complete everything a large machine can, but will fit in smaller spaces such as a doorway or hallway. Therefore, which machine you need will largely depend on the jobs you plan on doing.

Weight is also important to consider. We have discussed how rotary grinders are often heavier than planetary. When grinding concrete extra weight can be useful in removing those hard-to-remove surfaces. To combat this problem, many grinders have a weight system that can be added and removed so that you have the right downward head pressure for the job. Therefore, in the past, a rotary might have been your only solution when buying a heavier machine. Today though, you have many options that ultimately will come down to what the contractor wants.

Enjoyed reading this post? Read the following articles: